The highly anticipated race was finally becoming a reality. The realization that racing in Monaco would not be cancelled as it was the year before us finally came. Everyone was eagerly looking forward to finally leaving to Monaco, although most were anxious as well. You never have the feeling that there’s been enough testing.

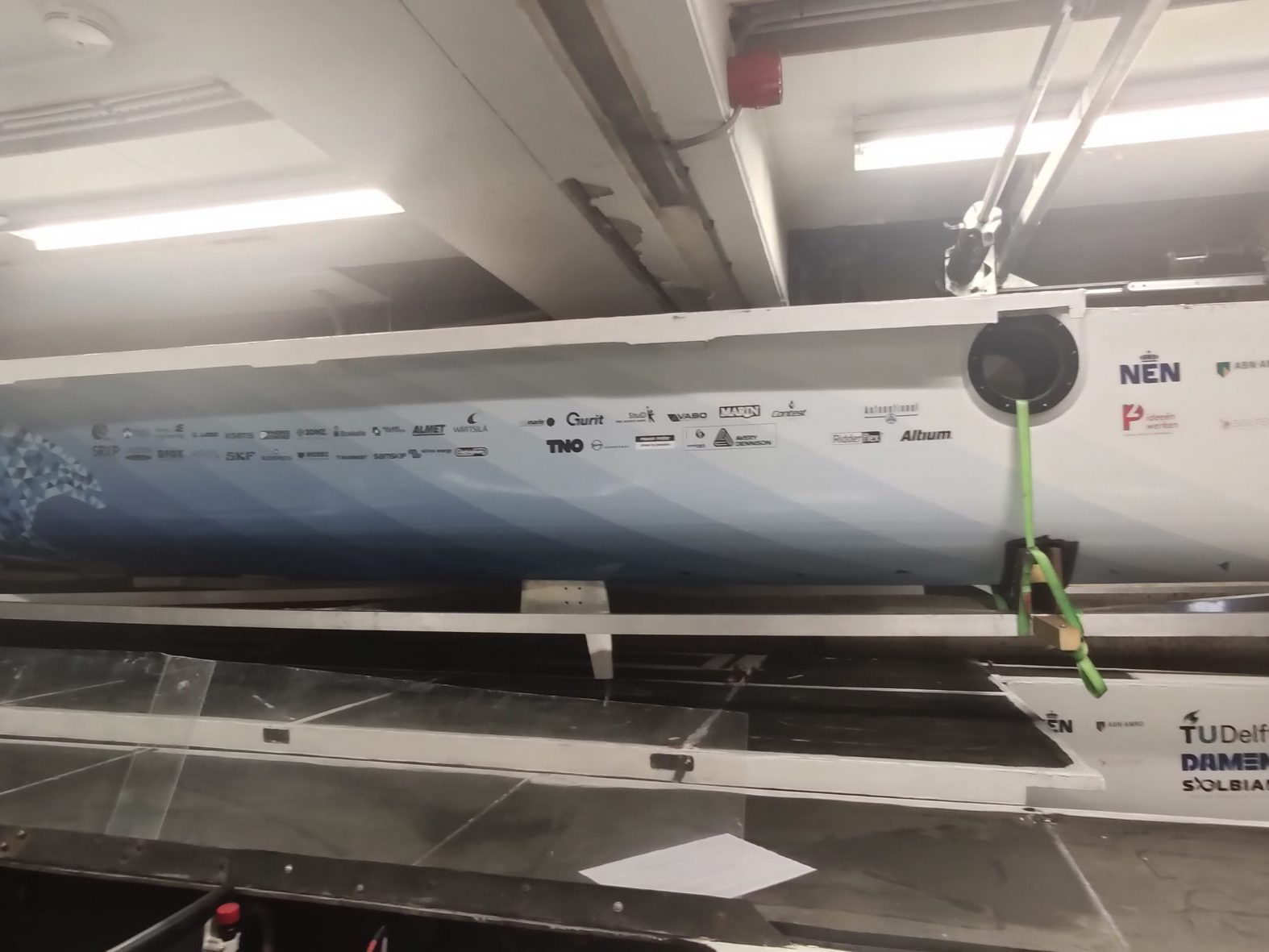

The first days in Monaco were mostly assembling the boat and the technical inspections. Of course, exploring Monaco and trying to get into the casino was also something we had to do.

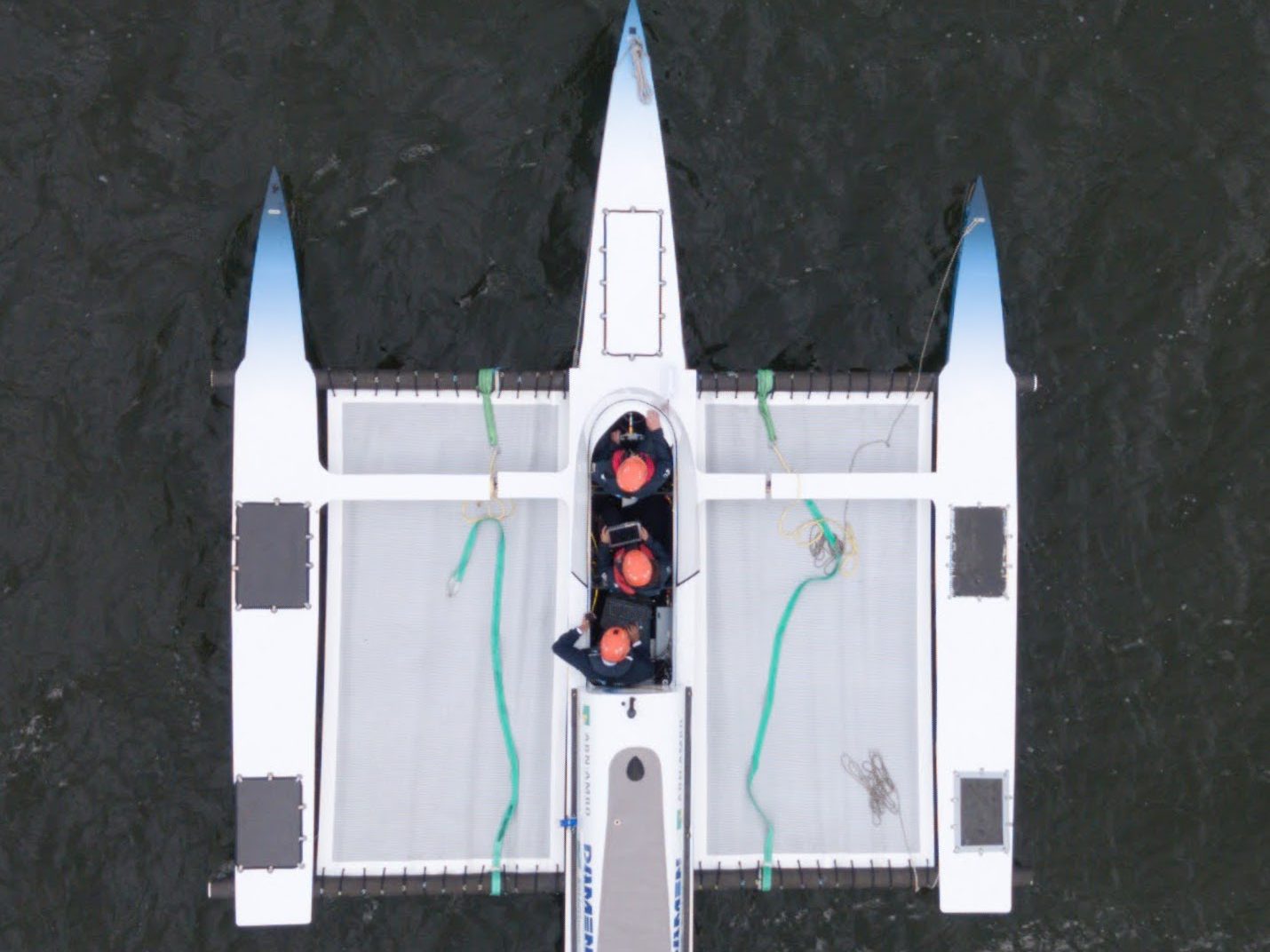

After getting through the inspection, we had a day to sail on the sea and fine-tuning the height control in these waters. We only had limited hydrogen fuel however, and getting more gas was not an option, so we had to be careful with how long we test for. The next day, our first challenge started, the maneuverability challenge. We did not score too greatly however on this with such a wide boat.

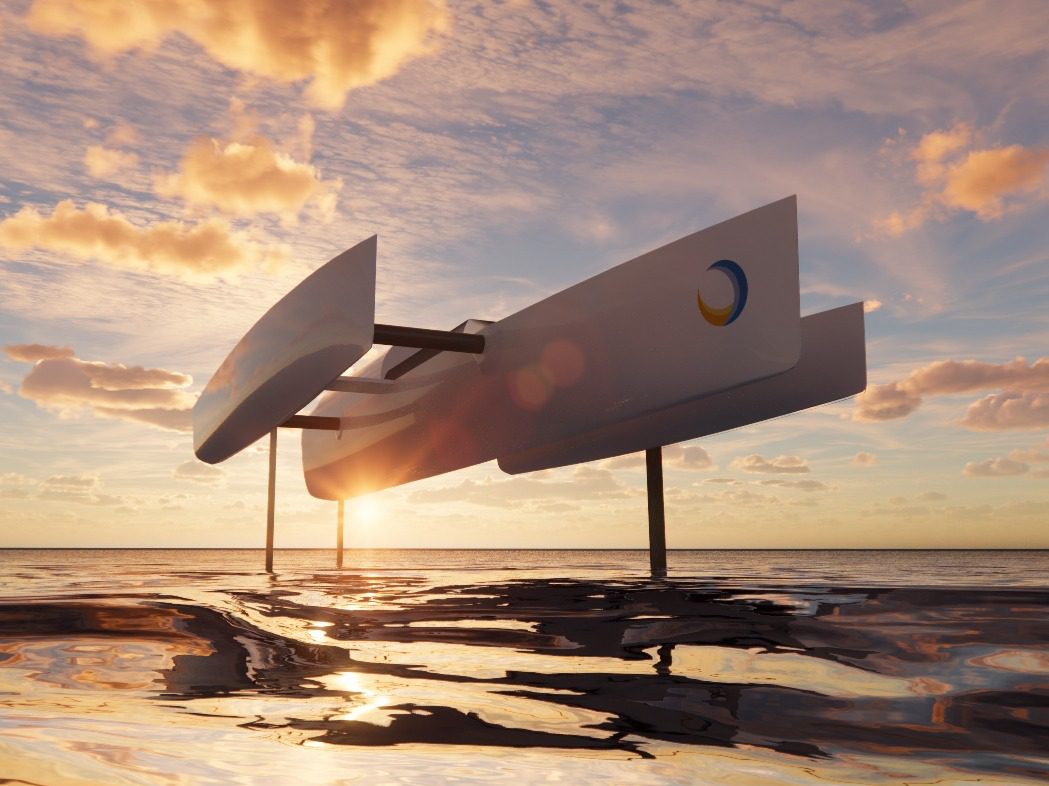

Our second challenge was coming up, the 16 nautical mile race. Here, we would have to complete this distance in the shortest time possible. Our boat is however made for long distance, so we focused mostly on the race for the next day, that would be 6 hours of sailing the longest distance possible.

This 16NM race did not go as hoped unfortunately. After some distance onto the rough sea, the boat did not fly smoothly, the waves were way bigger than predicted and the boat was not fine-tuned for this. At a certain point the boat stopped working and we were brought back to shore.

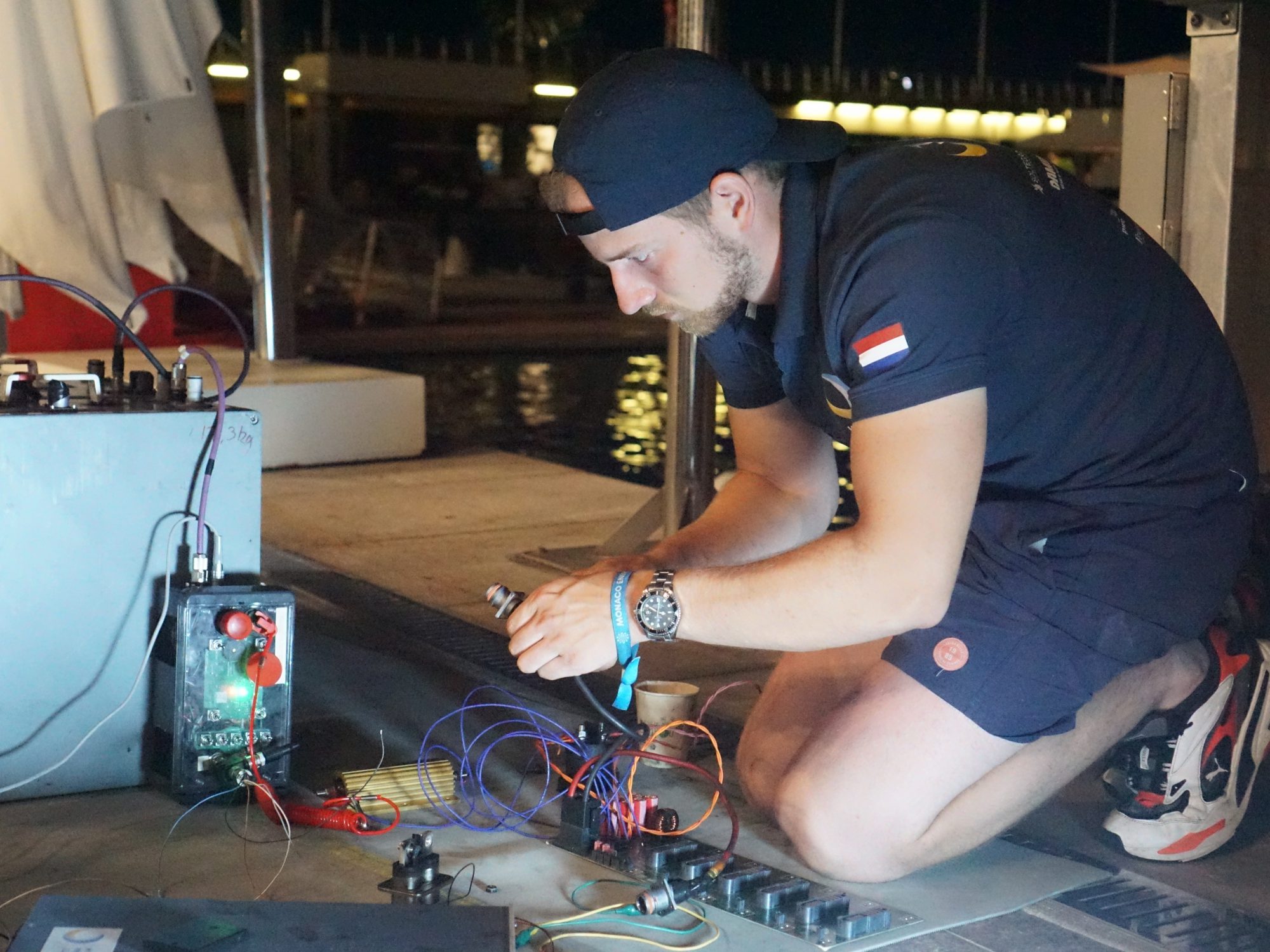

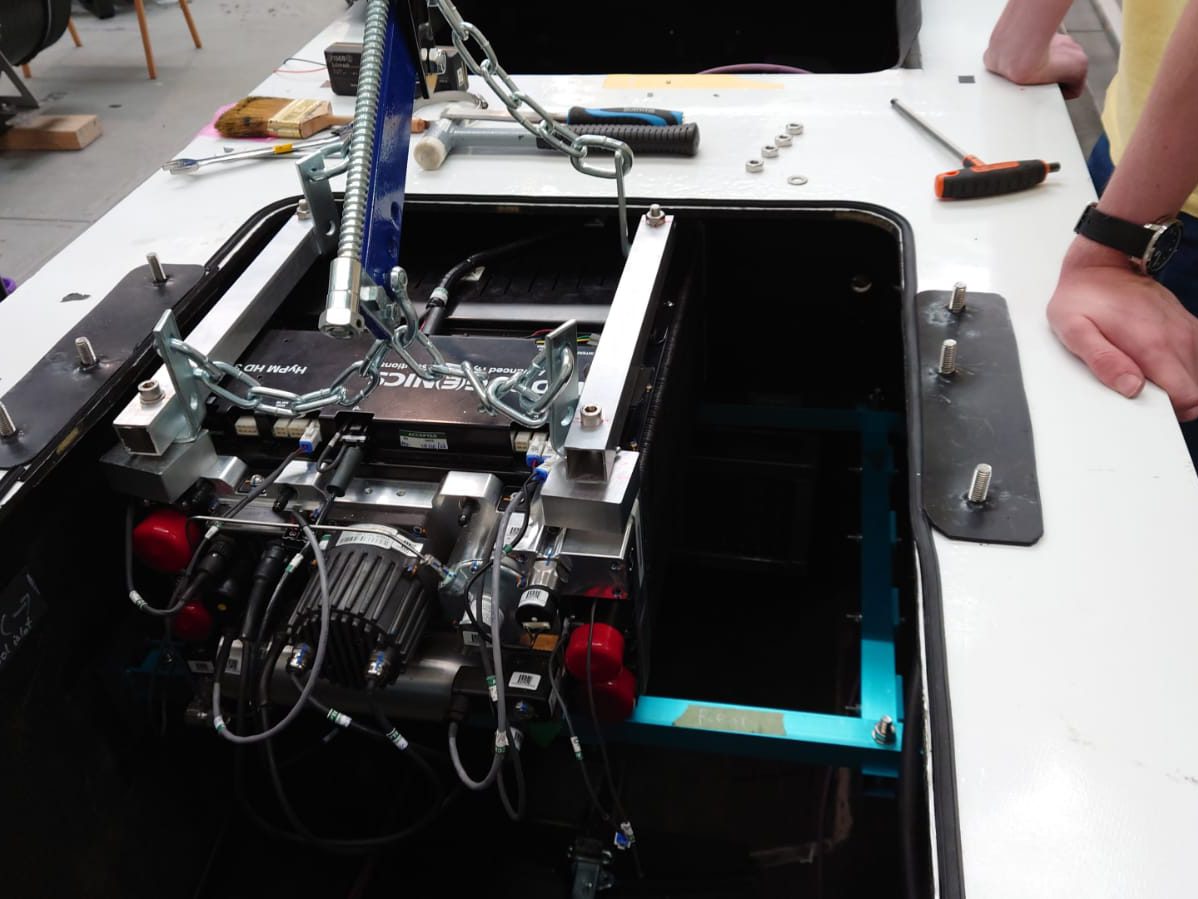

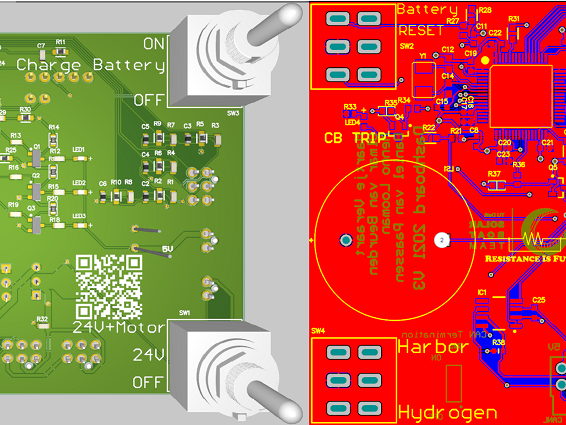

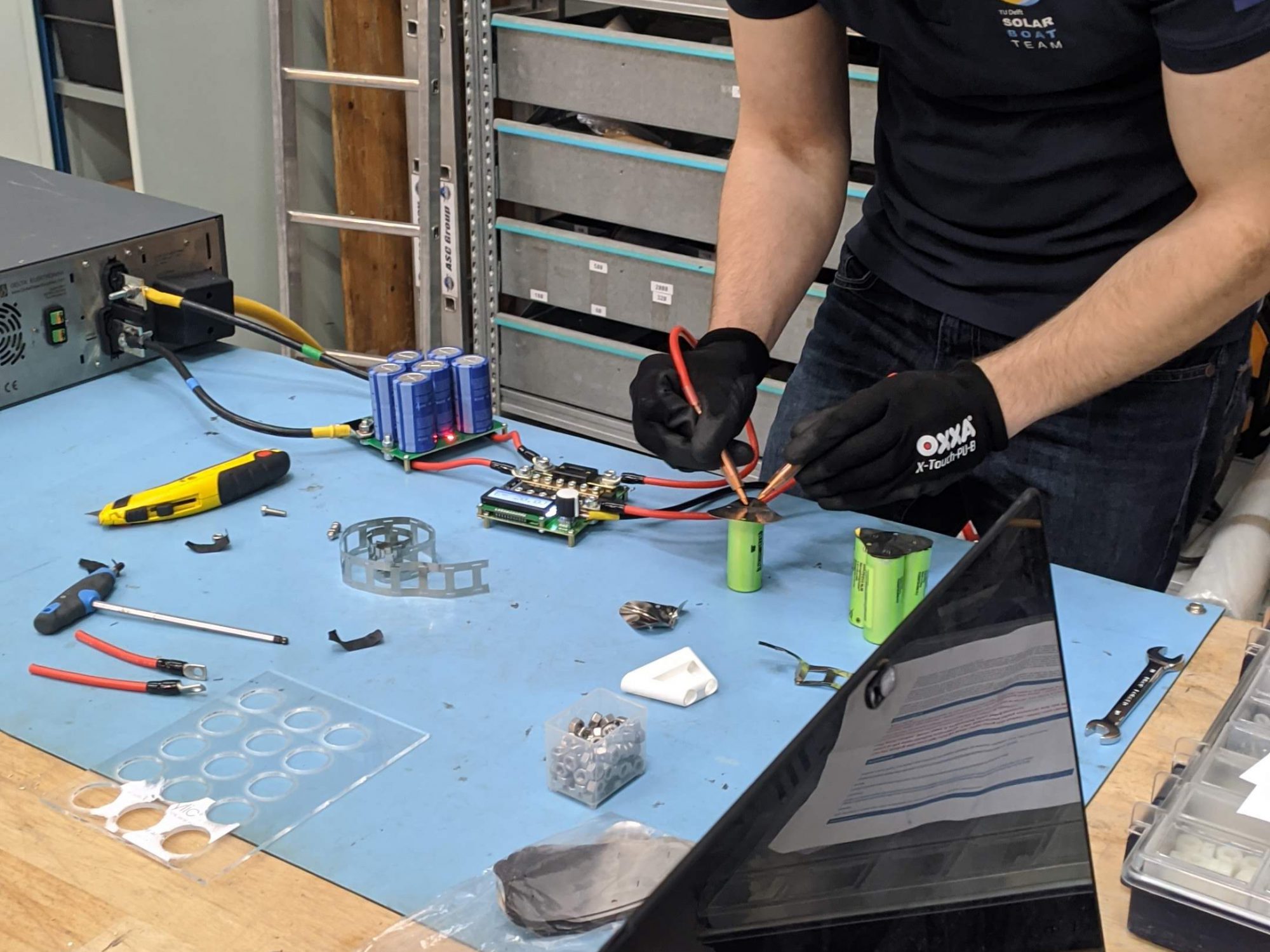

When we were all settled back in the harbor, we saw that it was our electrical converter that was broken. The converter was very damaged and we could not get it working that day. All of us spend that entire day (and night) doing everything that was possible, but that was not enough.

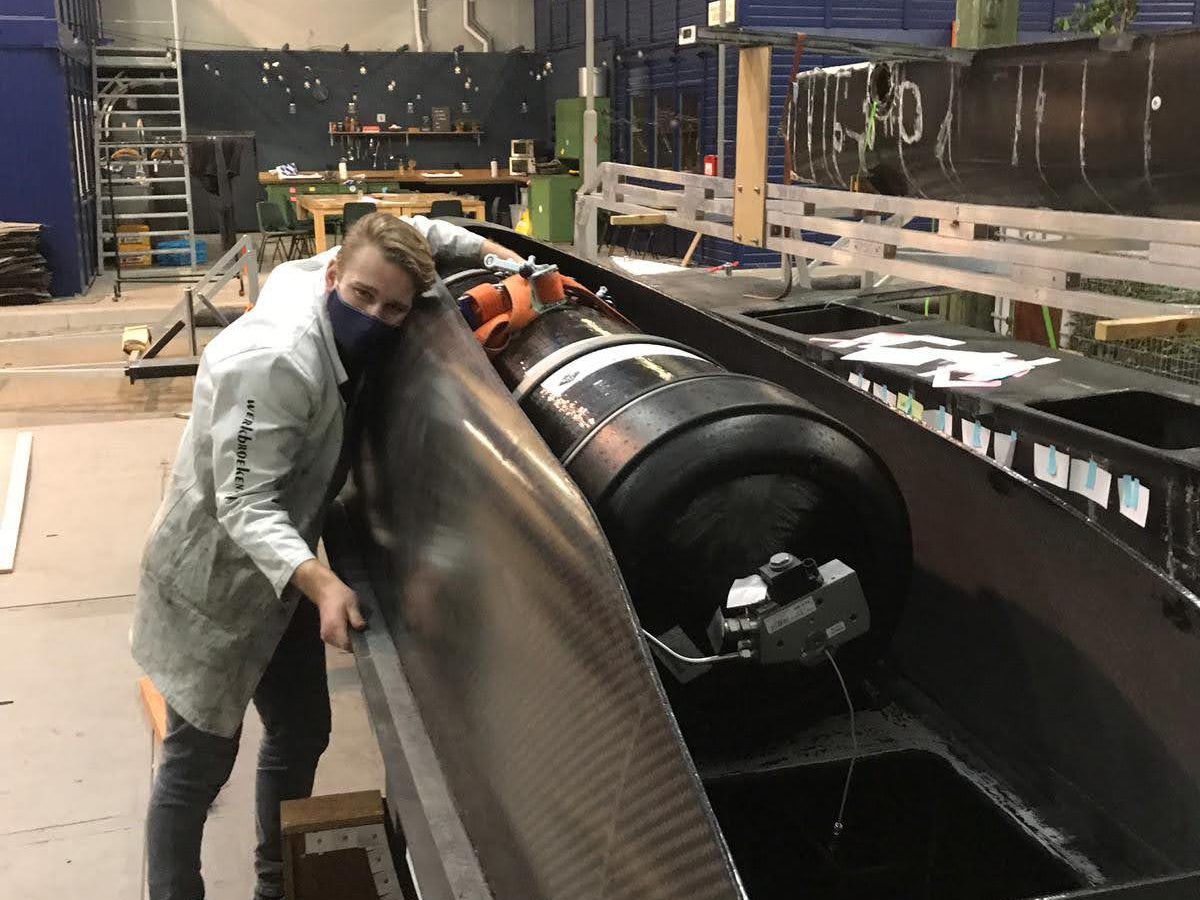

This was the moment we accepted that our highly anticipated long distance race would not even start for us, but also the moment we reflected on the great things that we had achieved. We had built the FIRST foiling hydrogen boat in the world and actually flew in the open sea in Monaco. There were a lot of doubts that we could achieve that from third parties around us. We had mixed feelings but were mostly really proud of what we pulled off. At the day of the awards, we were not expecting any (obviously), but to our great surprise we won the New Generation prize! Which is given to the team that brings a novelty to the market.